Fix the root cause of No-Call No-Show with help from TeamSense

Table of Contents

- Why “Call a Manager” Breaks at Scale

- What Actually Works at Shift Start

- Why Minutes, not Policies, Drive ROI at Shift Start

- Why App-Based Tools and Traditional Call-Off Hotlines Fail on the Frontline

- How TeamSense Makes The Entire Team's Life Easier

- Implementation That Keeps Pace With a Plant Launch

- When Call-Offs Work, Everything Else Gets Easier

In most manufacturing plants, the call-off process doesn’t feel broken until it is.

On paper, “just call your supervisor” sounds simple. In reality, it means missed calls before sunrise, texts sent to the wrong person, voicemails checked too late, and information scattered across phones, inboxes, and shift notes. By the time the shift starts, everyone’s reacting instead of planning.

This shows up fastest in growing plants. As headcount increases, shifts multiply, and leadership layers form, the cracks widen. What worked with 30 employees quietly collapses at 130. Not because people aren’t trying, but because the process was never built to scale.

Call-offs aren’t a policy problem. They’re a timing problem. And in manufacturing, timing is everything.

Why “Call a Manager” Breaks at Scale

The moment a plant starts hiring in waves, the call-off process becomes a stress test.

Absences don’t arrive neatly. They come in early mornings, late nights, and right before shift start. One employee calls HR. Another texts a supervisor. Someone else leaves a voicemail that doesn’t get heard until the line is already running short.

At small scale, people compensate. Managers forward messages. HR fills gaps. Someone keeps a mental list.

At larger scale, that stops working.

What breaks first:

- There’s no single source of truth. Information lives on individual phones, not in a shared view.

- Operations finds out too late. Coverage decisions happen after the shift is already compromised.

- Notifications hit the wrong people. Some leaders get woken up unnecessarily; others don’t get alerted at all.

- There’s no clean record. Patterns are hard to see, and accountability turns into hearsay.

None of this shows up in a process doc, but it shows up on the floor.

That’s why scalable call-off management isn’t about adding more rules or reminding employees what to do. It’s about replacing an informal, person-dependent process with something consistent, immediate, and visible without slowing anyone down.

No one wants to talk to their boss or a 1-800 stranger to call off. Text changes everything - Reducing No Call No Shows.

What Actually Works at Shift Start

A call-off process only works if it helps the plant make decisions before the shift is already in trouble.

At shift start, no one is looking for a perfect system. They’re looking for fast answers:

- Who’s out?

- Who knows?

- What needs to happen next?

The most reliable call-off processes work because they solve for three different needs at the same time without creating extra steps for anyone.

For employees: one message, no guesswork

Frontline employees don’t think in workflows. They think in moments.

They wake up sick. Their car won’t start. A family issue comes up. In that moment, they do what feels fastest and safest: call or text a person they know.

A scalable call-off process meets employees where they already are. One message. Plain language. No app to download. No login to remember. No training session, they barely recall from orientation.

When reporting an absence is obvious, employees use it. When it’s confusing or inconsistent, they don’t, and the breakdown lands on operations.

For operations: immediate visibility, not message forwarding

Operations leaders don’t need more notifications. They need clarity.

The difference between a manageable call-off and shift-start chaos often comes down to minutes. Knowing who’s out early creates options. Finding out late removes them.

What works is a single, shared view that shows:

- Who is out and for which shift

- Where coverage gaps exist

- What’s already been acknowledged

That visibility turns call-offs from interruptions into inputs. Instead of chasing messages, leaders can focus on coverage decisions while there’s still time to act.

For HR: fewer interruptions, cleaner records

HR often becomes the default call-off hub not because it’s ideal, but because the process around it is unclear.

When absences come in through scattered calls and texts, HR ends up answering the same questions repeatedly, manually logging information, and reconstructing what happened after the fact.

A structured call-off process creates a byproduct HR rarely gets otherwise: consistency.

- Consistent data.

- Consistent routing.

- Consistent records that support both day-to-day operations and longer-term decisions.

When call-offs are handled cleanly at the front door, everything downstream gets easier

Why Minutes, not Policies, Drive ROI at Shift Start

Most call-off problems aren’t caused by bad attendance policies. They’re caused by late information.

Plants usually already have attendance rules, escalation paths, and disciplinary frameworks. What they don’t have is a reliable way to surface absences early enough for those policies to matter.

At shift start, minutes create or remove options.

When leaders find out about an absence with time to spare, they can:

- Pull from a backup list

- Adjust assignments before the line starts

- Shift coverage without disrupting the rest of the team

- When they find out late, those options disappear. The result is costly downtime, overtime, or running short and hoping the impact is manageable.

That’s where the ROI actually shows up.

The value of effective call-off management isn’t in the system itself. It’s in what it prevents:

- Fewer last-minute scrambles

- Less time spent chasing information

- Fewer reactive decisions that lead to overtime or production delays

This is why improvements here pay back quickly. You’re not changing behavior through enforcement; you’re changing outcomes by improving timing.

Over time, better timing also creates clearer patterns. When call-offs are logged consistently and early, it becomes easier to spot issues tied to specific shifts, roles, or constraints like transportation and scheduling using attendance data. That’s where longer-term fixes start.

But it always starts the same way: getting the right information to the right people before the shift is already underway.

The Costly Impact of Absenteeism on Manufacturing Operations

Learn how chronic, unplanned absenteeism is a costly impediment to manufacturing productivity and efficiency, and how you can reduce absenteeism.

Why App-Based Tools and Traditional Call-Off Hotlines Fail on the Frontline

On paper, both apps and call-off hotlines make sense.

Apps promise structure and tracking. Hotlines promise simplicity. In reality, both tend to break down in the moments that matter most.

When something goes wrong, someone wakes up sick, their car won’t start, a family issue comes up, and frontline employees don’t want to navigate a system. They want to communicate quickly and move on.

That’s where both approaches struggle.

App-based call-off tools fail because they introduce friction at the worst possible time. If reporting an absence requires installing software, remembering a password, or clicking through menus, many employees will bypass it entirely, especially months after orientation, when training is a distant memory.

Traditional call-off hotlines fail for a different reason: they’re rigid. Employees wait on hold, leave voicemails, or call outside staffed hours. Messages get missed, misheard, or checked too late. By the time operations finds out, the shift is already impacted.

In manufacturing environments, both models struggle because:

- Not every employee has reliable data, storage space, or comfort using apps

- Training fades long before the first stressful call-off moment

- Phone policies and shift schedules complicate access

- Hotlines don’t provide real-time visibility or confirmation

- Stressful situations demand the simplest possible action

Even when these systems technically exist, adoption becomes uneven. Some employees use them. Others revert to calling or texting a person they trust. Managers end up monitoring multiple channels at once, which puts the plant right back where it started.

Text-based call-off workflows succeed because they remove friction entirely. Employees already know how to send a text. There’s no app to install, no number to memorize, and no waiting on hold. The message goes through, the right people see it, and the process keeps moving.

That simplicity isn’t a compromise. It’s the reason the system holds up as headcount grows, shifts multiply, and the plant gets busier, not calmer.

How TeamSense Makes The Entire Team's Life Easier

TeamSense is built for the realities this process usually breaks under: early mornings, multiple shifts, mixed access to technology, and constant change.

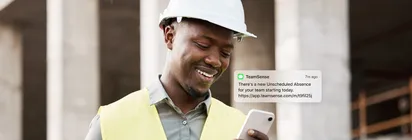

Instead of forcing frontline employees into apps or asking managers to act as message routers, TeamSense uses SMS as the entry point. Employees report call-offs the same way they already communicate by sending a simple text. From there, TeamSense handles the structure behind the scenes.

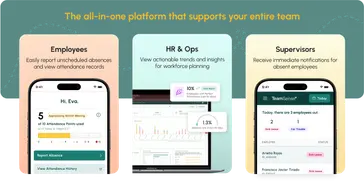

For manufacturing teams, that means:

- A consistent, text-first call-off workflow that replaces calls, voicemails, and side texts

- Real-time visibility in a web portal designed for shift coverage, not HR paperwork

- Notifications routed to the right leaders based on role and preference without alert fatigue

- A setup that works during plant launches and scales cleanly as headcount grows

TeamSense also removes the “do it twice” problem. Teams can start quickly with a basic roster and simple rules, then add integrations with timekeeping, payroll, or HR systems later without changing how employees report call-offs.

Once that connection with the frontline is established, many teams expand beyond call-offs into surveys, forms, and answers to common HR questions using the same channel employees already trust.

The result is fewer surprises at shift start, less time spent chasing information, and a call-off process that actually holds up as operations scale.

Implementation That Keeps Pace With a Plant Launch

Plant launches move faster than systems. Headcount ramps in waves. Policies evolve. Ownership shifts. Most teams don’t have the luxury of waiting until everything is finalized to fix critical processes.

That’s why call-off management has to work in motion.

TeamSense is designed to go live quickly without forcing early decisions that create rework later. Teams can start with a simple roster upload and a small set of call-off reasons, then refine routing and notifications as roles and shifts settle.

There’s no requirement to replace existing timekeeping or payroll systems to get value. Call-offs can be handled as their own workflow focused on timing, visibility, and communication, while integrations come later, when systems are ready.

Just as importantly, the frontline experience doesn’t change as the system matures. Employees report call-offs the same way from day one. Operations uses the same real-time view. HR gains cleaner data behind the scenes without retraining the workforce.

This approach lets teams move forward during launch without locking themselves into decisions they’re not ready to make yet, or slowing the operation while they wait.

When Call-Offs Work, Everything Else Gets Easier

A reliable call-off process does more than solve attendance problems. It creates something most manufacturing teams struggle to build: a dependable connection with the frontline.

Once employees are consistently using a single, simple way to report absences, communication stops being fragmented. Messages aren’t split across calls, voicemails, and side texts. Everyone knows where information lives and who sees it.

That consistency unlocks other workflows that typically bog teams down.

HR can use the same text-based channel to collect forms and acknowledgements without chasing paper or emails. Operations can send quick, targeted surveys to understand what’s affecting attendance or shift coverage. Employees can get answers to common questions about benefits, leave, or policies at the moment they need them, not weeks earlier during orientation.

Because these workflows use the same system employees already trust for call-offs, adoption isn’t a separate challenge. There’s no new app to roll out and no extra training to schedule. The channel is already proven.

The result is less back-and-forth, fewer interruptions, and more clarity across the plant. Instead of reacting to problems as they surface, teams gain a way to address issues earlier and more consistently.

When call-offs work, communication stops being a constant source of friction and starts supporting the operation instead of slowing it down.

About the Author

Jackie Jones, Employee Engagement & Attendance Specialist

Jackie Jones has over three years of experience helping HR teams improve employee morale, reduce absenteeism, and create happier, more engaged workplaces. With a strong background in employee relations and attendance management, she brings practical strategies and insights that support frontline teams and the HR professionals who lead them.