Fix the root cause of No-Call No-Show with help from TeamSense

In the world of manufacturing, every minute counts. From automotive assembly lines to manufacturing equipment to food processing plants, the efficient operation of machinery and processes is vital to meet production targets, maintain quality, and maintain profitability.

But let’s face it: sometimes machines stop, employees are excessively absent, supply chains are disrupted – and productivity grinds to a standstill. Manufacturing downtime happens, and it can be frustrating.

But, costly unplanned downtime, is more than just an inconvenience. The high costs of an experienced unplanned downtime in manufacturing can quickly have far-reaching impacts on your company’s bottom line and market reputation. According to Forbes, unplanned downtime can cost manufacturing companies a whopping $50 billion per year.

Let’s delve into the high cost of downtime in the manufacturing business, explore why downtime occurs, and most importantly, uncover tangible costs and the strategies that can reduce it.

What is Downtime in Manufacturing?

Downtime is a pretty straightforward concept: it refers to the period of time when production activities come to a halt. This can happen for any number of reasons, from planned interruptions for upgrades, adjustments, or maintenance, to unplanned disruptions caused by human error, breakdowns, or supply chain interruptions.

Regardless of the cause, downtime is something you want to avoid. Its effects are severe, impacting not just production output but also employee morale.

Planned vs Unplanned Downtime

In the manufacturing process, downtime can be categorized into planned and unplanned interruptions.

- Planned downtime is deliberately scheduled. This would be time for scheduled maintenance, repairs, upgrades, or adjustments to machinery. It might cause a pause, but planned downtime is actually proactive because it prevents breakdowns and prolongs the lifespan of your equipment.

- Unplanned downtime, on the other hand, refers to the costly halts caused by equipment breakdowns, human errors, and supply chain disruptions. Due to its unpredictable nature, unplanned downtime costs companies 35% more per minute than planned downtime.

Causes of Downtime in Manufacturing

Now that we know what downtime is, it’s time to dive into the reasons it happens. Downtime stems from a variety of sources that can disrupt operations and impact the bottom line.

With manufacturing facilities suffering an average of 20 downtime incidents a month, let’s investigate a few of the most common causes.

Machine Breakdown

In the manufacturing industry, machines breaking down is one of the most common causes of unplanned downtime. Equipment failure and technical glitches can bring a production line to a sudden halt.

In fact, the average manufacturer faces 800 hours of unplanned machine maintenance and downtime a year. That’s about 15 hours per week that you’re paying your people to sit and wait for machines to get up and running.

Bottom line: don’t be among the 70% of companies that are unaware when their equipment is due for maintenance. Get ahead of machine and maintenance schedules to avoid costly downtime.

Employee Absences

Occasional absences are unavoidable, but too many absences can throw your whole system off. Unplanned employee absences can be especially disruptive and can lead to productivity gaps, particularly if there are no backup personnel available to fill in.

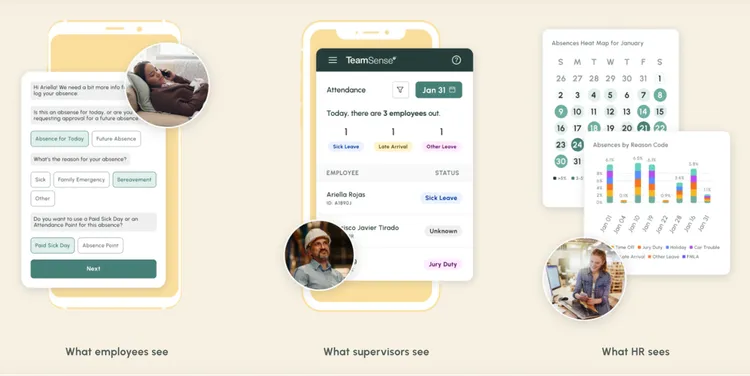

If absenteeism is causing downtime, consider attendance software like TeamSense to revolutionize your employee attendance protocols. TeamSense’s text-based absence management tools help manufacturing and warehousing teams reduce absenteeism and downtime without headaches, endless paperwork, or confusing technology.

Employees just send a keyword via text to their company's number and complete the straightforward survey they get back. Managers receive real-time notifications and can then use our other text messaging features to conveniently manage open shifts.

With 100% adoption and zero complaints, we’ve finally created a call-in method that both employees and supervisors buy into.

Supply Chain Disruptions

No industry has been so disrupted by supply-chain issues as manufacturing, with 60% of manufacturing companies reporting these delays weekly. Manufacturers rely on a complex web of suppliers industrial manufacturers and vendors to provide raw materials manufacturing machinery, and components.

Disruptions to manufacturing supply chains, an unexpected event such as delayed deliveries or shortages, can lead to production stoppages significant delays and lost revenue.

Human Error

Humans make mistakes, and there’s no way around that. But, human error can be mitigated by proper onboarding procedures and continued education. When employees are improperly trained, they can make mistakes operating machinery, handling materials, or following processes, resulting in costly errors that require time-consuming corrections.

In fact, human error was found to be a more common cause of unplanned downtime in manufacturing than in any other sector in 2017. Train your people to avoid finding yourself among the 48% of manufacturers who indicate that there is significant room for improvement in proactive prevention.

Get a free new-hire onboarding checklist here.

Outdated Processes

If you’re holding onto outdated processes or manual record-keeping methods, it’s time to let them go! Old systems are more prone to breakdowns and are less capable of keeping up with modern production demands…ultimately leading to additional costs and more downtime.

Technological solutions such as employee self-service technologies and innovative manufacturing processes and software can improve efficiencies, streamline your operations, and other cost factors ultimately reduce downtime.

The Costs of Downtime In Manufacturing

More downtime means lost revenue. And a lot of it is lost business: Aberdeen’s research found that companies lose an average of $260,000/hour to downtime – and that’s an average.

The financial impact of downtime can affect various aspects of your entire business, and your company’s financial health. Let’s break down where all that lost money is coming from.

Labor Costs

Direct labor costs refer to how quickly your employees produce completed items. If your employees are sitting around waiting for machinery or manufacturing software to be up and running, you end up paying them for non-productive hours.

Fortune Global 500 manufacturing firms are estimated to lose a cumulative 3.3 million hours of labor a year to unplanned downtime.

Production Costs

When you have a strict production schedule, the last thing you want is unplanned downtime. Downtime can disrupt your schedule, leading to inefficient use of resources and materials. In fact, when asked what type of increase in productivity they would expect to see if downtime was eliminated, businesses projected a 50% increase.

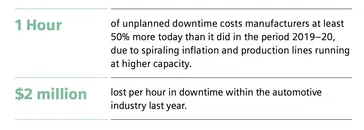

In other words, less downtime would lead to major gains. And get this: with the spiraling inflation and higher-than-ever production costs, each hour of unplanned downtime costs at least 50% more today than it did in 2019.

Startup Costs

Restarting production after downtime requires time and resources. Machinery needs to be recalibrated and processes must be set back in motion. All of this costs money – including energy surge costs, percent of reduced or lost production time, recycling costs, quality inspection, and rework costs.

Overhead Costs

Even when you’re experiencing machine downtime, your overhead operations continue. Fixed costs such as rent, utilities, and maintenance don’t go away when a machine goes down, adding another cost to the total price tag on your downtime cost.

Potential Sales

Downtime means a loss of sales and market share. Fortune Global 500 companies reported losing 11% of annual revenues to downtime in 2023. Missed production targets due to downtime can lead to lost production, delayed shipments and unmet customer demands. And most likely, an unhappy customer is not coming back.

How to Calculate the Costs of Downtime in Manufacturing

If it seems tricky to calculate the cost of downtime, you’re not alone. Over 80% of companies fail to calculate their downtime costs correctly. And if you can’t define your problem, it can be challenging to find the solution.

Thankfully, there’s a formula to help. First, determine the hourly cost of downtime by adding your labor costs, your overhead costs, and your production costs. Then, multiply it by the duration of the scheduled downtime or event.

Cost of Downtime = (Hourly Labor Cost + Hourly Overhead Cost + Hourly Production Cost) x Downtime Duration

How to Reduce Downtime in Manufacturing

Calculating the cost of your downtime might have sent you reeling. But fear not: there are tried-and-true strategies to using downtime tracking maximize efficiency and maintain a competitive advantage.

This next section will go over some top methods and strategies for reducing downtime in your manufacturing plant or warehousing business.

Track Downtime & Identify Causes

The first step is to diagnose the problem. Implement a system that will help you monitor downtime events and identify their root causes. Once you understand why downtime is happening, whether it’s from machines breaking down or confusing employee attendance policies, you can get a clearer picture of how downtime is negatively impacting revenue.

Improve Employee Attendance Rate

Addressing employee absenteeism is crucial in maintaining smooth production. This is especially true for unplanned absences or “no-call no-shows.” The last thing you want is to find yourself scrambling for coverage, causing more downtime.

Consider having a rotation of employees on call to pick up shifts when needed, using an employee attendance point system, or implementing an attendance improvement plan.

Or, make it simple with an efficient attendance management system. Attendance solutions like TeamSense offer real-time attendance tracking and insights and allow management to seamlessly connect with employees and communicate attendance expectations, ultimately optimizing workforce management.

Use Planned Downtime for Predictive Maintenance

Instead of waiting for your machinery to be on the fritz, schedule some planned downtime for predictive maintenance. Seven out of ten businesses see predictive maintenance as a strategic priority, with one in three dedicating a team solely to predictive maintenance.

And for good reason. During scheduled equipment downtime, equipment conditions are monitored and preventative maintenance actions can be taken before failure occurs. Get ahead of the problem and you’ll save time and money.

Offer Employee Training Programs production downtime

One of the best ways to reduce downtime is to make sure your teams know company policies and procedures like the back of their hand. Investing in employee training ensures that your people can properly operate machinery, know how and when to call out of work, and adhere to established workplace processes.

And, as a bonus, companies with robust training programs are said to have a better workplace culture.

Monitor Software & Machines downtime costs

If you want to reduce downtime, make sure your technology is up to date. Regularly updating software systems and performing preventive maintenance on machinery can prevent technical glitches and breakdowns.

Thanks to leading software and machinery, downtime incidents are on the decline. Though 20 monthly unplanned incidents of downtime may sound like a lot, this is actually six fewer incidents than in 2021. Largely, this is thanks to digitization and predictive maintenance efforts.

Prevent Manufacturing Downtime with TeamSense

If you’re tired of wasting time and money due to downtime, then it’s time to take action. You can reduce the substantial costs and consequences that ripple through every aspect of your business by understanding the causes of downtime, quantifying its costs, and implementing effective strategies to reduce it.

Innovative solutions like TeamSense offer a comprehensive approach to tackling employee attendance issues, which are a common cause of downtime. From precise absence tracking to integration capabilities with your existing HR systems, TeamSense provides you with real-time data and actionable insights so that you can proactively manage workforce attendance, streamline operations, and reduce the risk of production interruptions.

Make downtime a thing of the past.

About the Author

Sheila Stafford, CEO | Leader in Applied AI for Frontline Productivity

As CEO of TeamSense, Sheila Stafford is at the forefront of increasing productivity for frontline teams through AI-driven solutions. Her visionary approach combines cutting-edge technology with a thoughtful focus on enhancing human connection; Sheila strategically implements AI where it adds the most value while recognizing the critical role of personal interaction and ensuring that human engagement remains central when it matters most. Under her leadership, TeamSense is redefining how companies support and engage their frontline teams for a more connected, efficient workplace.