Fix the root cause of No-Call No-Show with help from TeamSense

Table of Contents

Agile Manufacturing is an operating strategy that empowers facilities to respond quickly to changing scenarios without causing downtime, hurting profit margins, or sacrificing product quality. It uses flexible equipment and layouts, cross-trained teams, short planning cycles, and real-time data so you can make changes to plans within hours – not weeks. By implementing Agile Manufacturing strategies, operations teams can run smaller batches and execute faster changeovers, resulting in shorter lead times to meet variable demand spikes without inflating costs.

Implementing Agile Manufacturing concepts can help factories build resiliency in the face of variable demand or supply chain disruptions, ensuring that they can optimize their resources even as production needs or capabilities evolve.

In this guide, we’ll walk through the principles of Agile Manufacturing, and provide tips on how you can implement this strategy in your manufacturing facility so that you can respond quickly to changing conditions.

How Does Agile Manufacturing Compare to Traditional or Lean Manufacturing?

Before drilling down into the fundamentals of Agile Manufacturing, it can be helpful to see where the operational philosophy sits compared with other structures you may already be familiar with – traditional (or “Waterfall”) project management, and Lean Manufacturing.

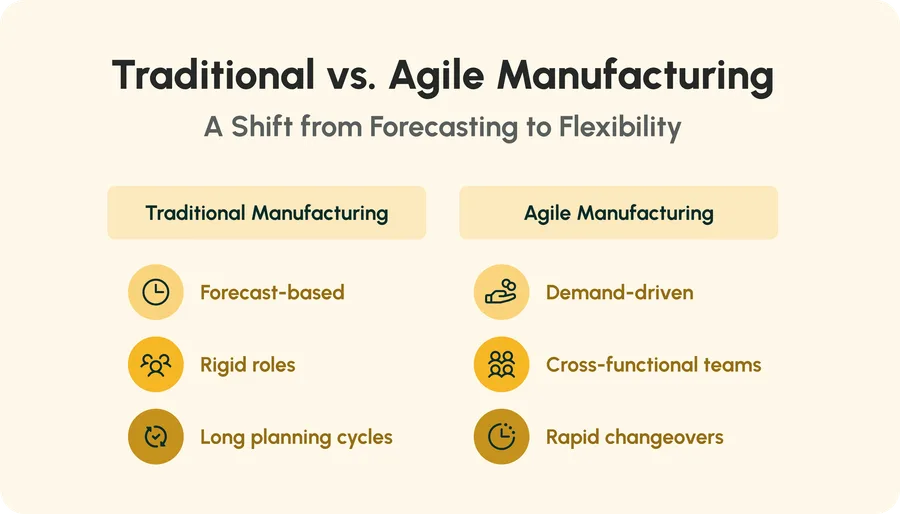

Traditional v. Agile Manufacturing

Traditional project management for manufacturing relies on driving efficiency through structured, consistent processes, with capacity planning driven by market forecasts. They may plan their production cycles months in advance, with minimal opportunity to revise plans.

Agile Manufacturing turns that process on its head: In Agile, operational planning is driven by current demand, with highly iterative processes for optimizing production based on what’s needed at that point in time.

While traditional manufacturing relies on a static workforce, with each employee playing a set role in the production cycle, the Agile Manufacturing workforce is often cross-functional. Employees are trained across a variety of roles so that they can support shifting production needs. This enables teams to adapt quickly to evolving operational needs, with reconfigurable cells supporting small-batch production to meet demand without overproducing.

Traditional manufacturing tactics can be a good fit for facilities that have static output and consistent demand – but for factories that are prioritizing innovation by producing a broad mix of products, or those that see unpredictable spikes in demand, moving to an Agile Manufacturing model can help you cut costs, preserve quality, and shift gears more quickly to keep pace with market needs.

Lean v. Agile Manufacturing

We’ve previously written about Lean Manufacturing, another modern manufacturing philosophy that factories are using to cut costs and streamline production. While it has some overlap with Lean Manufacturing, Agile Manufacturing focuses on optimizing for versatility, rather than solely reducing waste.

Lean focuses on eliminating unnecessary work and material usage to cut costs and streamline processes to build stable, reliable production cycles. Agile methodology is also focused on streamlining operations, but with an eye towards versatility – for instance, enabling cross-trained staff to quickly shift production from one SKU to another with minimal downtime.

Lean and Agile manufacturing methods include some of the same elements, and can be used in tandem – but Lean Manufacturing is more applicable to facilities with predictable needs, whereas Agile is a better fit for manufacturers with fluctuating demand or production capabilities.

The Core Pillars of Agile Manufacturing

Now that we’ve explored the ways Agile Manufacturing varies from other common operational philosophies, let’s look at the key elements that define Agile Manufacturing.

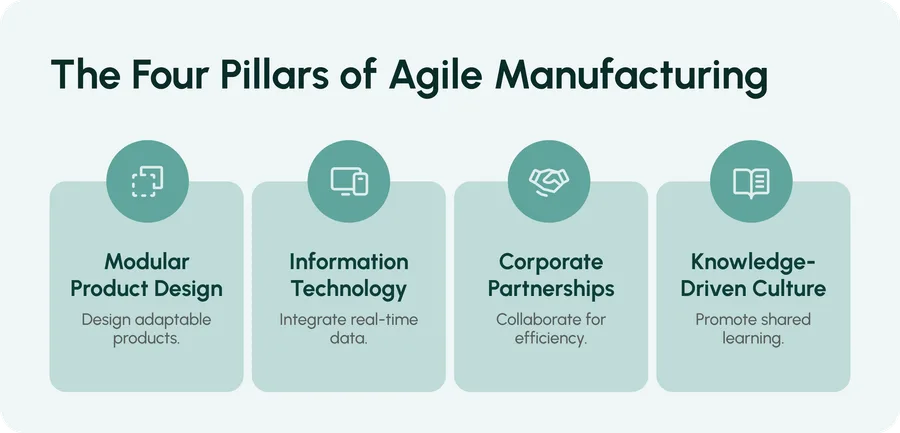

Six Sigma defines the core pillars of Agile Manufacturing as:

- Modular product design

Modular product design refers to designing products that use a core base, with flexible components that can be adapted to new use cases. That means a base product model can be easily configured to support production of dozens of new SKUs. For example, a refrigerator manufacturer might produce products with a common cabinet and compressor/electronics core, with modular door sets, ice/water modules, and shelf packs added later to create dozens of models. - Information technology

Agile Manufacturing relies on real-time signals to support demand and monitor quality control, so it’s important to build a robust and integrated IT structure that connects the entire manufacturing process from end-to-end. Facilities should incorporate AI-driven technology including IoT-connected sensors and predictive maintenance equipment to monitor the health of all their assets, ensuring that they can spot issues early and limit equipment downtime. Likewise, you can also rely on software tools for optimizing your human resources, such as using automated scheduling and attendance management tools to help you forecast labor availability and plan a daily production schedule that maximizes the value of your available workers’ skills. - Corporate partnerships

Manufacturing facilities can keep infrastructure costs down by focusing on building strategic partnerships with other collaborators – including suppliers, tech vendors, and other manufacturing facilities. Focusing on expanding your capabilities by tapping into a broader ecosystem can help your facility drive innovation and gain access to key resources and expertise on tap, without overinvesting in resources internally. - Knowledge-driven culture

Finally, Agile Manufacturing thrives on a culture of gaining and sharing expertise. Employees focus on developing multiple certifications and skills, and generously share their knowledge and best practices throughout the organization. By establishing standardized practices for each factory initiative, your team can get up to speed on new roles quickly – and with a culture of learning that encourages everyone to contribute input, you’ll be able to build on your processes through continuous innovation.

By bringing together these four key elements, manufacturing organizations can set up a framework that helps them grow their business sustainably, even in the face of unpredictable challenges. With an Agile approach, manufacturers are able to make rapid pivots that preserve capital, allocate resources efficiently, and enable them to meet changing demand and industry constraints.

Key Tools and Processes for Supporting Agile Manufacturing

Ready to make the move to an Agile Manufacturing process? Here are some foundational steps to help you get started – outlining the tools and technologies that will support your transition.

Prioritize Quick Changeovers

Facilitating fast changeovers can help you minimize downtime and help you diversify your production capabilities. By ensuring your team members can quickly close out a production cycle and make the transition to a new product, you’ll be able to boost their productivity and minimize material waste.

Some key concepts to support quick transitions include:

- Single-Minute Exchange of Die (SMED)

This concept focuses on identifying opportunities to dramatically reduce changeover time – in many cases, to less than 10 minutes. SMED prioritizes performing as many changeover stops as possible while the line is still running, so that your downtime between production runs is minimal. As one example of SMED in action outside of the manufacturing world, NASCAR pit crews use SMED techniques to change all four tires on a racecar within 12 seconds.

- Cellular layouts

As with Lean Manufacturing, Agile manufacturers minimize wasted energy and time by optimizing the layout of their facilities. By arranging equipment and workstations in a U-shaped line, employees can complete multiple steps with minimal walking between stations, reducing equipment needs and expediting production cycles.

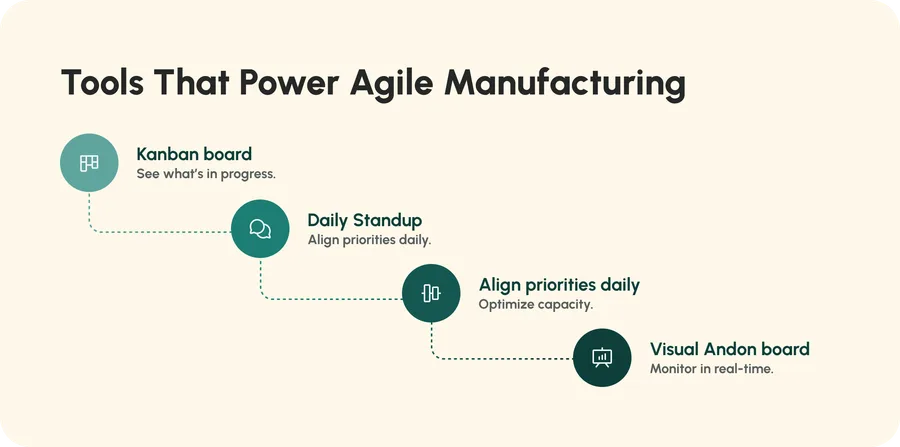

- Kanban board

Kanban boards provide a visual representation of workflows in progress, providing a transparent way for all stakeholders to understand what’s been done, what’s in progress, and what needs to be done. Used heavily to support project management across many industries, Kanban boards make it easier to understand the status of current projects and see where bottlenecks are occurring, so that you can make adaptations to the operational plan when needed.

- Standard Work + 5S

Standard Work refers to creating standardized processes for each task, with documented steps and timing to ensure that it is easily replicable. 5S is a cleaning and organization system that employees can use for their workstations: Sort, Set in order, Shine, Standardize, Sustain. By pairing the two systems, employees can boost productivity, reduce errors, enhance product quality, and ensure quick changeovers.

Plan for Limited Production Runs

Agile Manufacturing relies on demand-based production, so it’s important to keep a close pulse on your inventory needs and resource capacity so that you can plan accordingly and reduce the risk of over- or underproduction. Focus on these concepts:

- Daily standup meeting

In Agile methodology, each team comes together at the start of a shift for 10 to 15 minutes to verbally review what they’ve recently accomplished, what they’re working on, and any roadblocks in their way. By getting clarity around priorities each day, supervisors can make changes to production cycles to align with high-priority goals, and make scheduling adjustments to ensure productivity stays high.

- Finite capacity scheduling

Using finite capacity scheduling tools, often as part of an Advanced Planning & Scheduling (APS) software solution, enables your facility to optimize your production schedules based on your actual resources – including your available labor (factoring in break times), your open machines, material availability, cycle time, and due dates. By using these tools, you’ll be able to build an efficient production calendar that loads jobs based on priority level to optimize utilization rates, helping you maximize efficiency.

- Visual management (Andon)

An Andon is a visual display board – similar to a leaderboard – that illustrates the status of production at each of your running production lines. You’ll be able to see the number of planned units v. the actual output, and the number will light up in the event of an equipment glitch or if an employee calls for assistance. An andon is a powerful tool for real-time monitoring on the factory floor, with the opportunity to provide real-time feedback to minimize downtime.

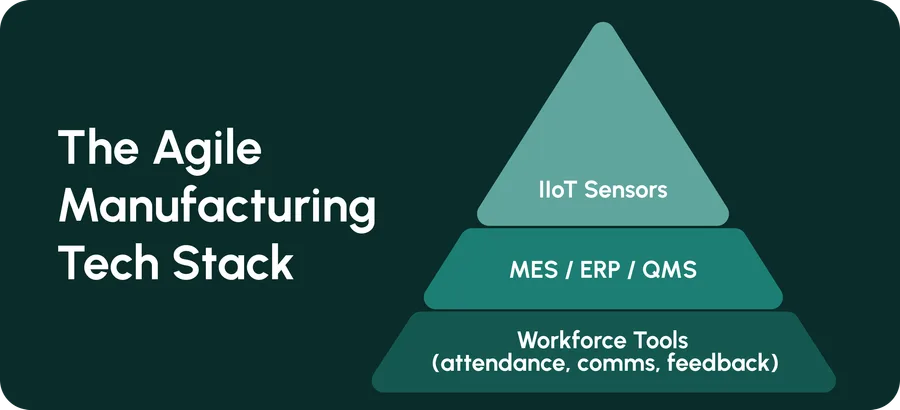

Build an Integrated Tech Stack

Setting up a highly integrated tech stack is essential for ongoing monitoring of your operations, so you’ll have enhanced visibility around whether you’re meeting production goals or whether you’re having resourcing issues. Some of the most important technologies to include are:

- Manufacturing Execution System (MES)

Your MES releases dispatch lists, tracks WIP, enforces routings/recipes, collects real-time production data and e-records. It’s a crucial tool for supervisors and ops leaders to ensure transparency around real-time status, so that they can pivot quickly as needed.

- Enterprise Resource Planner (ERP)

Your ERP ties together data around orders, BOMs, routings, inventory, and costing. With clarity around your available inventory and what components are needed to produce each SKU, you’ll be able to plan restocks more efficiently and avoid material waste.

- Quality Management System (QMS)

Rather than referring to a specific software solution, a QMS refers to your organization’s framework and processes for monitoring product quality. It’s important to set up a system that includes critical checks at various points during the production cycle, which will help you capture defects and drive corrective actions. By doing so, you’ll be able to keep quality control high, and reduce manufacturing time spent working on goods that won’t make it through the production cycle.

- IIoT-enabled equipment

By equipping your machinery with Industrial Internet of Things (IIoT) sensors, you’ll be able to monitor real-time data around metrics including temperature, humidity levels, and vibrations. You’ll receive automated alerts when data points fall outside of their “safe zones,” which could indicate a problem with the machinery or require manual intervention. By setting up an alert system to spot issues in real-time, you’ll be able to circumvent the risk of larger equipment failures, and prioritize preventative maintenance.

Optimize Your Workforce

Finally, don’t forget that the people who power your production lines are key to your success. While you may be able to automate parts of the production process, it’s crucial to know that you have the right team in place to manage and monitor the process from start to finish.

To ensure you have the right people in the right roles to streamline efficiency, focus on these priorities:

- Cross-training matrix

If your production capabilities are versatile, your frontline team members should be, too. Encourage each team member to cross-train to gain new skills and certifications, so that they can meet compliance requirements to move between stations. Thorough training across disciplines will reduce the risk of safety issues, increase team members’ value to the organization, and put them in line for promotions that will boost their retention rate. - Rapid comms and attendance management tools

Using attendance management tools like TeamSense enable supervisors to send real-time alerts about plant closures, shift availability, safety notices, and other important broadcasts, to keep your team informed at all times. Employees can also use TeamSense’s text-based attendance notification tool to provide instant updates around unplanned outages, giving shift supervisors real-time insights around workforce planning that they can use to optimize scheduling and adjust production cycles. - Feedback loops

By employing Pulse surveys through TeamSense, you can get quantitative data from your frontline team that you can use to shape and iterate on executive decisions, ensuring that you can keep morale high when making changes. Providing personalized feedback, both in daily stand-up meetings and in 1-on-1s, gives supervisors the opportunity to connect directly with their team members to help them navigate roadblocks, helping them improve performance and productivity.

By implementing TeamSense, one wood pallet manufacturer was able to transform their company culture – leading to reduced absenteeism, and increased accountability through a transparent points disciplinary system. With attendance management technology in place, supervisors and their frontline teams are able to communicate more effectively, ensuring that employees get the support they need to keep productivity and attendance rates high. Now, the facility has the attendance data it needs to optimize scheduling for maximum efficiency, while keeping absentee rates low.

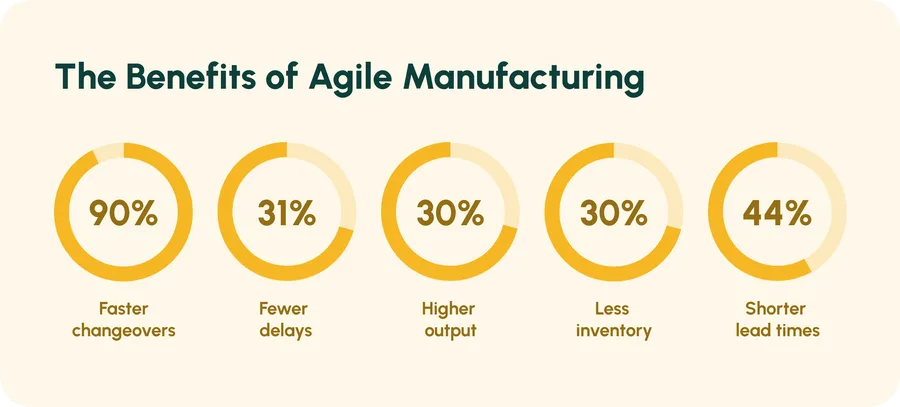

The Benefits of Agile Manufacturing

Making the shift to an Agile strategy can help you make your facility more competitive and resilient in the face of changing variables. Here are some tangible results you’re likely to see:

- Faster changeovers

With a SMED framework in place, you may be able to take your production line changeover time down from hours to minutes. SMED-style work often cuts setup time by 50–90%, so you can run smaller, mixed batches without adding downtime. - Fewer production delays

With better insights around your supply chain, shorter planning cycles and the ability to shift strategies quickly to account for resource availability, you’ll likely see your on-time delivery rate go up substantially. After implementing advanced scheduling and other Agile practices, Coca-Cola Singapore saw on-time deliveries improve by 31%. - Increased output without adding equipment

By optimizing your production cycles and minimizing downtime, your factory can expect significant efficiency gains, with throughput increasing by up to 30%. - Reduced overstock and excess materials

More accurate forecasting around product demand can help you reduce inventory of WIP/finished goods. By using Lean and Agile technologies to improve visibility and reduce waste, one factory was able to cut their inventory levels by 30%. - Shorter lead times

Facilities that optimize their production lines and make use of AI-enhanced technologies will be able to ship orders much more quickly, enabling them to deliver a great customer experience and reduce cashflow issues. After using AI technology to enhance their manufacturing efficiency, AstraZeneca saw lead time drop by 44%.

Agile Manufacturing not only expedites production and eliminates waste – it clears a pathway for greater innovation. By building your team’s skills across disciplines and promoting a culture of knowledge-sharing, you’ll be able to create an environment where everyone is free to share ideas around process improvements, or even brainstorm new product ideas. That means you’ll be able to more easily iterate on what’s working to develop new products, or improve existing products in line with employee feedback.

At a time when supply chain disruptions are more common than ever, shifting to Agile processes helps you build resiliency into your business plan. Rather than shut down operations in response to roadblocks, you’ll have the structure in place to help you pivot effortlessly – whether that means bringing in off-duty employees to fill labor gaps, or shifting the production cycle based on material shortages. With enhanced visibility around your entire operational structure, you’ll have the data at hand to make smart decisions in response to changing market conditions, helping you effectively future-proof your business.

Agile Manufacturing gives you the power to monitor your business in real-time to see what’s working and what’s not – and the freedom to iterate, experiment, and innovate. By embracing Agile Manufacturing strategies, your facility will not only run more efficiently today – you’ll be able to map a strategy with the flexibility to see you through the years to come, whatever comes next.

About the Author

Devin Frosheiser, Director, Industry Strategy and Community

Devin Frosheiser is the Director of Industry Strategy & Community at TeamSense, where she fosters a community for manufacturing and operations leaders to share insights, capture ROI, and drive meaningful employee engagement. With a background spanning General Motors, Amazon, and Yanfeng International Automotive Technology, she brings deep experience in manufacturing, logistics, operations, and procurement.

Devin's expertise allows her to help TeamSense customers uncover the hidden costs of hourly absenteeism and turnover. Formerly Sr. Manager of Indirect Procurement at Yanfeng, Devin sourced TeamSense while seeking an attendance solution and was inspired by its power to boost productivity and quality of life for frontline teams.