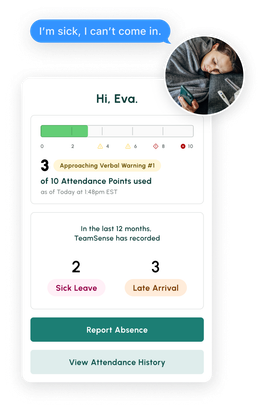

Fix the root cause of No-Call No-Show with help from TeamSense

To say a lot has happened in the manufacturing industry during the last few years is an understatement. The industry has weathered a global pandemic (and all the fallout from it) while still growing into the Fourth Industrial Revolution and what it holds for the future of manufacturing.

Ripple effects from supply chain disruption, inflation, and labor shortages still plague manufacturing, but the industry is moving forward into a new era of reinventing processes and protocols in 2023. Expect to see these trends in manufacturing continue throughout the year.

3 Trends in Manufacturing in 2023

In our latest white paper, we dive into many manufacturing industry trends coming in the new year. Download the full report to learn more, but in the meantime, here are three of the trends in manufacturing for 2023.

1. Employee Retention Remains a Top Priority

With employees leaving companies in droves, expect one of the top trends in manufacturing to center around reducing turnover and boosting retention in 2023. A Deloitte survey found that attracting and retaining a quality manufacturing workforce is a top priority for 83% of manufacturers they surveyed.1

Thanks to “The Great Resignation,” companies are more concerned about retaining top talent within their building. However, if wages stall, benefits decrease, and burnout continues, that may prove challenging. Still, team member retention remains top of mind for the future of manufacturing.

2. Cost of Materials Rising with Inflation

One of the most prominent U.S. manufacturing industry trends is a word most people have heard all about lately—inflation. Like most industries in the last few years, manufacturing is no stranger to feeling record-breaking inflation. In fact, 76% of manufacturing leaders list increased raw materials cost as one of the most significant issues facing manufacturers.2

When the cost of materials rises, the cost to produce items increases, eventually leading to price jumps passed on to the consumer. And with the Federal Reserve forecasting that inflation will continue throughout 2023, it’s clear that manufacturing could see even more price hikes for the materials they’re producing.3

Is your call-in process terrible? Text reduces no-shows and absenteeism by up to 40%.

Don't believe us? Check out this case study to see how this 3PL benefited.

3. Automation Powered By AI, IIoT, and Smart Factories

Looking at manufacturing operation trends in 2023, Automation and AI (artificial intelligence) aim to scale production to become faster, standardized, and more efficient. Not to mention cutting back on workplace injuries and OSHA violations.

In the automotive industry, smart factories are estimated to create $160 billion in value by 2023 and beyond.4 In fact, the automotive industry seems to be leading the charge, with 70% of automotive companies already having a smart factory initiative.5 As we move forward into the decade, expect new trends in manufacturing to revolve around these new technologies and innovations.

The Future of Manufacturing in 2023

Through all the changing manufacturing industry trends, the industry remains resilient and hopeful of what’s to come. Ready to learn more? Get even further trends, forecasts, and insights for what the future of manufacturing will look like in 2023 with our white paper, 2023 Trends and Forecasts in U.S. Manufacturing.

Download the 2023 Trends and Forecasts in U.S. Manufacturing Guide

About the Author

Sheila Stafford, CEO | Leader in Applied AI for Frontline Productivity

As CEO of TeamSense, Sheila Stafford is at the forefront of increasing productivity for frontline teams through AI-driven solutions. Her visionary approach combines cutting-edge technology with a thoughtful focus on enhancing human connection; Sheila strategically implements AI where it adds the most value while recognizing the critical role of personal interaction and ensuring that human engagement remains central when it matters most. Under her leadership, TeamSense is redefining how companies support and engage their frontline teams for a more connected, efficient workplace.