Fix the root cause of No-Call No-Show with help from TeamSense

Tens of thousands of employees use TeamSense every month to call-off from work, complete employee satisfaction surveys, or download company policies. We look at that usage data and it gives our company insight into absenteeism that spans many companies, industries, geographical regions, and time periods. We share those benchmarks with our clients and coach them on ways to boost productivity, optimize efficiency and inspire employee engagement.

Our customers’ data, when pooled together, gives us clear insight about what happened with absenteeism in 2023. We want to share some of those insights with you, our dear readers. As happens every January, pundits and prognosticators predict what’s going to happen in the coming year. Sometimes we agree. Sometimes not.

I recently co-hosted a TeamSense webinar with our COO and Co-Founder Alison Teegarden to discuss some trends we saw in 2023 customer data and weigh in on some of the predictions that may or may not have so much real-life data behind them.

You can watch the entire webinar below.

TeamSense Findings Over The Last 12 Months

The “When”: Tuesdays are tricky, and the New Year starts sluggishly

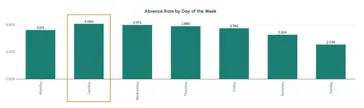

If we were to stop 100 people on the street and ask them, “What day of the week do you think has the highest employee absence rate?” most of us would argue between Monday and Friday as the worst days for attendance. Of course people are more likely to take those days off to extend their weekend, right?

How many would answer Tuesday? In fact, across more than half a million absence days in 2023…wait for it…Tuesdays, Wednesdays, and Thursdays had a higher absence rate than either Monday or Friday.

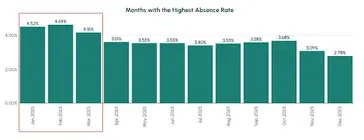

Absence rates by month in 2023 are also counterintuitive, at first look. Why would absence rates be significantly higher in January, February and March than for months later in the year? Wouldn’t employees feel rested and rejuvenated after some time off for the holidays? What about kicking off the new year with goals of earning more or performing well at work?

Those factors may be in play, but there are at least two plausible reasons for higher absence rates in the first quarter of the year. They may reinforce each other and they probably have a stronger effect than R&R for the holidays or New Year’s resolutions about professional excellence.

First, many companies have attendance policies with an annual number of permitted absences, and that allotment resets at the beginning of the calendar year. On January 1st, employees feel wealthy with vacation days, and so they’re more likely to take them towards the beginning of the year.

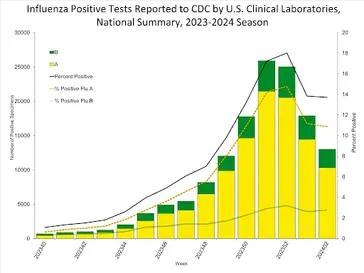

Secondly, flu season peaks at that time of year. The following data from the Centers for Disease Control and Prevention (CDC) shows that TeamSense absence data reflects the peak of flu season (not to mention other seasonal illnesses like colds that peak in the Winter.)

But what about December, which represents weeks 49-52 in the chart above? December had the highest rates of flu infection but showed the lowest absence rate by far in the TeamSense 2023 absence data (2.78%). Disclaimer: TeamSense does a lot of great things, but it does not prevent illness. This is where there may be a relationship between an employee’s remaining balance of permitted absences and when the flu season kicks in.

Folks who might normally call off in December–either because they’re feeling the early stages of illness or they’re helping pick up the slack for sick relatives–are less likely to take a day in December when they don’t have many sick or vacation days left to take. Flu season is still on in January-March, and employees have sick days so they use them.

This is only my guess from looking at the data in aggregate. TeamSense customers who see similar data in their own TeamSense dashboard, will see patterns in their local context of one plant or one warehouse. They will see their own patterns that I can’t see from a distance of 500,000 absence days across the U.S. and Canada. What part did local weather play in absences from illness, transportation or FMLA-related absences? Did any of the company’s programs help minimize those factors?

Which brings me to the next big question: why were workers calling off in 2023?

The “Why”: Illness is Still the Biggest Reason for Call-Offs, Then Vacation and Late Arrivals

We analyzed the half million absence days recorded in TeamSense to see the reasons why people called off from work. But before discussing the data we do have, I’ll mention what’s not there: the infamous “no call, no show”. These are unplanned, unexcused absences that are not reported to the employer before the absence occurs.

In general, there are two types of no call, no shows:

Quiet quitting – Dissatisfied employees may still take a paycheck for a while, even if they’re actively looking for a new job. As you might guess, these quiet quitters are less likely to take the time to report an absence. More on quiet quitting later in this post.

Call-off noncompliance – These are people with no intention of leaving the company but who find the call-off process too difficult, time-consuming, or annoying when they are facing illness, inundation, or injury. The cost of spending minutes on hold or navigating a phone tree feels like too much in the moment, so they skip it.

It’s safe to say that no call, no shows are underreported in our data, even though our clients have seen dramatic reductions in no call, no shows with TeamSense. Our solution inspires engagement and creates connections, which reduce rates of quiet quitting. We also reduce call-off noncompliance because with our text-based, mobile solution employees can call off in a minute, without speaking to anyone. It’s fast and easy for the employee, and managers receive instant absence notifications.

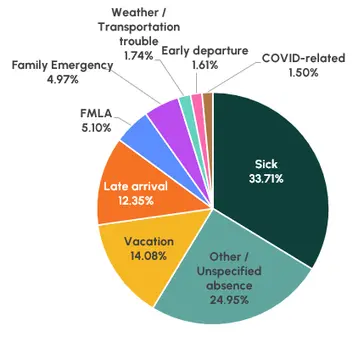

But among the absence reasons that TeamSense counted in 2023, the five most common were these:

Illness - 34%

This illness rate excludes absences marked as COVID-related, which surprisingly came in at only 1.5% of absences in 2023. TeamSsense was founded in 2020 in response to COVID-related absences. Had we drawn this chart then, the proportions would’ve looked very different. It’s nice to see these numbers so low.Other / Unspecified - 25%

This category highlights TeamSense’s low-code flexibility for configuration. Many absence reasons are grouped in this category, because each of our customers chooses the absence codes that match their policies. I couldn’t tell the meaning of some absence codes, so I threw them in this “Other” bucket. This is why we advise our clients to make absence reason codes as unique and specific as possible. Otherwise, they have as much trouble as I did understanding the meaning of codes like “Confidential”, “Low”, or “Rejected”. If you don’t know what it means, you can’t address it with policies or programsVacation - 14%

This number is likely lower than the actual number of vacation days taken by the general population. Most companies require employees to request vacation in advance, and not all TeamSense customers have enabled this workflow in their instance of TeamSense. Surely this number undercounts actual absences from vacation.Late arrival - 12%

Some portion of these absences are probably related to the “call-off noncompliance” mentioned above. Suppose that an employee faces a choice between waiting on hold for 10 minutes to notify her employer that she’ll arrive 20 minutes late, or saying nothing and just arriving 20 minutes late. She will be less late if she just comes to work and doesn’t bother telling anyone. But this decision means that–at best–the supervisor gets the absence information 20 minutes later. Especially during pre-shift prep, those 20 minutes matter. Multiply that 20-minute blind spot by many employees over many days, and it’s easy to see why a fast, easy way to call off dramatically improves BOTH policy compliance and staffing agility.Family and Medical Leave Act (FMLA) - 5%

This category of absence is a clear opportunity for employers to show compassion to their employees and inspire engagement. The normal sense of frustration with a slow, complicated call-off system can increase exponentially if the act of calling off takes time and attention away from nurturing a new baby, caring for a seriously ill family member, or recovering from a serious illness (all absence reasons covered by the Family and Medical Leave Act).

TeamSense Absence Data Mirrors National Trends

Some of our customers have thousands of employees using TeamSense, but even the largest probably don’t generate enough data to accurately reflect regional or national root-cause reasons for absenteeism. When we pool the data from all of the companies we serve, we have enough normally distributed data to feel confident in the larger patterns we see.

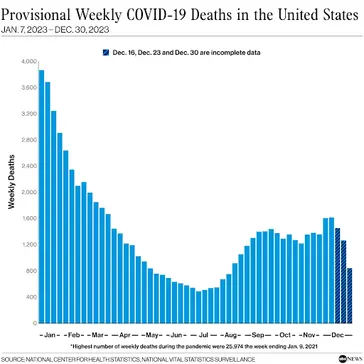

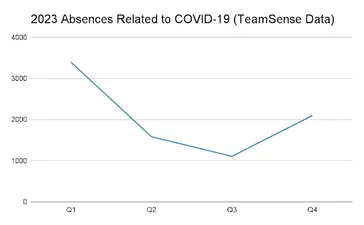

Take the COVID-related absences I mentioned above. In 2023, TeamSense users reported enough absences due to COVID to mirror national numbers collected by the National Center for Health Statistics, National Vital Statistics Surveillance, and reported by Mary Kekatos of ABC News in her piece titled, “Why are 1,500 Americans still dying from COVID every week?”

Now compare the curve above to the shape of the curve in COVID-related absences reported by TeamSense users in 2023. See the similarity?

It’s important to call out that the data from The National Center for Health Statistics counts deaths from COVID-19. We certainly hope that COVID absences reported using TeamSense were not fatal. Nevertheless, both charts show the same pattern in people getting sick with the virus.

These are only three of the many patterns we can find in the data captured by TeamSense. Every day, we hear about valuable insights that our customers find in their own site or company data. Check out the animated demo on this page to see how greater visibility provided by TeamSense helps HR teams curb excessive absenteeism.

Third-Party Predictions: Manufacturing’s Back!

But let’s look forward. January is when everyone makes predictions about what’s coming this year. We can use data on what happened in 2023 and enrich our understanding of expert predictions for the rest of 2024. Here are three notable January predictions, enriched with some of our perspectives and recommendations.

Goldman Sachs Research: US Manufacturing Is Having a Renaissance

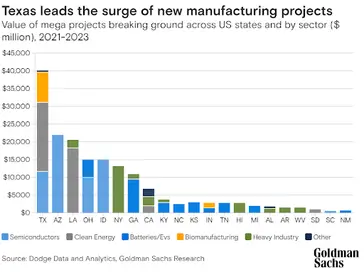

The Inflation Reduction Act was signed into law on August 16, 2022, along with the CHIPS and Science Act and the Bipartisan Infrastructure Law that same year. A year and a half after those laws went into effect, Goldman Sachs shared research under the headline “US Manufacturing Is Having A Renaissance.”

Goldman Sachs Research identified over $1 trillion in announced investments in manufacturing, $500 billion of which are “mega projects” – investments of over $1 billion. Those investments include semiconductor plants (43%), electric vehicles and batteries (22%), and clean energy projects (17%). Analysts predict that the build-out increased equipment orders in 2024. Despite delayed equipment orders due to project timelines, project activity for 2022 and 2023 is set to exceed $80 billion annually, a substantial rise from the $23 billion average between 2011 and 2021. Texas leads in breaking new ground for manufacturing projects, particularly in semiconductor manufacturing, comprising 25% of all US projects.

These analyst findings reflect what we hear from our prospects and customers in Texas, Arizona, Ohio and many of the other states cited in the research: they’re going to need more people when they open those plants.

We encourage those who have yet to begin operations at their new sites to plan early for their adoption of TeamSense. In fact, long-term customer The Pella Corporation had TeamSense in place at one of their sites as they were hiring staff in 2020 before ever beginning production and during the height of the COVID pandemic. Employees in that plant used TeamSense as an integrated part of their experience working at Pella, from the very first day of production.

Deloitte: Tight Manufacturing Labor Market Expected to Continue in 2024

Deloitte’s “2024 manufacturing industry outlook” opens with a discussion of “persistent talent obstacles” and this finding:

“In a recent survey conducted by the National Association of Manufacturers (NAM), almost three-quarters of surveyed manufacturing executives feel that attracting and retaining a quality workforce is their primary business challenge.”

This chart from the same report makes it easy to understand why workforce retention is such a big executive priority in manufacturing. It shows that there aren’t enough skilled manufacturing employees. There has been a manufacturing labor shortage since early 2021. It persisted through 2023 and into 2024.

One of Deloitte’s recommendations for managing this shortage caught my eye. The report says,

“Manufacturers should also think about ways to create new opportunities for upskilling existing employees. For example, companies could free up three additional hours a day per person by adapting digitization and automation and offer more training sessions to workers during those freed-up hours.”

Our customers tell us that they feel those very same time-saving benefits from the hours freed up by TeamSense. For example, LuAnn Shafer, HR Manager at The Pella Corporation shared how that digitization saves them time and money and improves efficiency and productivity at her site in Ohio. We here from many of our customers that they spend 5-10 hours every week just tracking attendance and racing to figure out if they have enough people to start production.

The Manufacturer & The Wall Street Journal: Growing Appreciation for Supply Chain Resilience Along with New Pressures on Logistics Ops

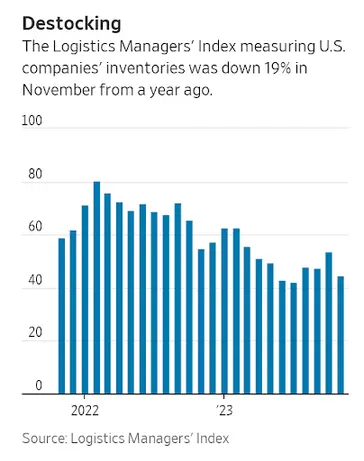

In “Predictions for the manufacturing industry in 2024” The Manufacturer predicted AI will add some supply chain predictability in 2024, and logistics are recovering from the peak days of COVID when companies were forced to hold so many supplies in inventory. The article stated that “average delivery times for production materials have dropped from 100 days in July 2022 to 87 days in August 2023” but “lead time for production materials is still yet to reach pre-pandemic levels.” As supply chains stabilize and adjust to post-COVID times, companies are holding less in inventory.

The article goes on to say that, “...manufacturing companies are becoming increasingly aware of the importance of readiness for unseen events. This means working toward more resilient supply chains – minimizing disruptions to maintain continuity as best as possible regardless of external challenges.”

Absenteeism poses one of the main risks of disruption and discontinuity to supply chains and to the manufacture and delivery of products. For example, TeamSense has many automotive suppliers as customers who make component parts for the Big 3 US automakers. During last year’s United Auto Workers (UAW) strike, those suppliers did not participate directly in the strike, since their employees were not members of the UAW. Nevertheless, the strike did put strain on those companies and threatened the future health of the automotive supply chain.

In an earlier blog post “How Automotive Suppliers Stay Connected to Their Teams During the UAW Strike” we explained how automotive suppliers worried that they might have to furlough or lay off workers as the UAW strike persisted. We shared some ways that TeamSense helped HR teams communicate with their workers during those stressful times. By making communication easy, HR teams using TeamSense maintained their connection with employees. They were able to improve engagement in a moment that threatened lots of disengagement.

The Wall Street Journal seemed to agree with The Manufacturer’s assessment that risks to supply chains will continue into 2024. An article titled “New Disruptions, Geopolitics Hang Over 2024 Supply Chains” describes how many importers are looking away from China as the world’s chief supplier of goods, for reasons of risk and uncertainty. Also, inventories are declining as mentioned above.

Let’s add this all up. There will probably be more demand for goods as the global economy recovers. New trade relationships will change shipping patterns, and there will be less room for error because of smaller inventories and operations nudging back towards just-in-time delivery schedules. This will all put added pressure on logistics and warehouse managers to be more nimble and optimize their operations. The same WSJ article summed it up this way:

“For logistics providers, the flexibility of their shipping customers means they have to respond with similarly nimble operations. “I don’t think we’re back to ‘just in time,’ but I think ‘just in case’ has been redefined at a lower level,” said Sidney Brown, co-owner and chief executive of NFI Industries, a trucking and warehouse provider for some of the country’s biggest retailers.”

What will this mean for the interlock between third-party logistics (“3PL”) companies and the manufacturers and retailers who rely on dependable supply deliveries? Everyone will have to do more with less.

One crucial area where 3PL companies can optimize operations (and improve margins) is by reducing overtime and minimizing overstaffing.

Both manufacturing and logistics companies count on reliable attendance by their hourly workers. If they’re missing people when a shift starts, they have to scramble to meet their production targets. They try to hedge against that costly disruption by overstaffing. If they staff 110% of the workforce needed to operate, they can still get by if there’s 10% absenteeism (not all that uncommon). Or they pay overtime for employees to stay later. This is expensive, and neither option is best for the dependable employees who are there every day with great attendance. This is why many major 3PL companies count on TeamSense for the staffing predictability they want. In fact, one such customer reduced absenteeism by 39% using TeamSense.

Major weather events also disrupt supply chains. Another TeamSense customer found itself in the path of Hurricane Idalia that hit Florida in August 2023. They closed the plant and then–even through flooding, hurricane winds and downed telephone poles–they used TeamSense’s text-based mobile messaging to check on the safety of their team members. The HR team quickly configured a Safety Check Survey and sent it out to all of their affected staff. Within 2.5 hours, they had close to a 100% response rate. They knew that their team members were physically safe, although many were without power or were stuck in place, some with severe damage to their homes. Team members felt the love in how the company looked out for them and responded with texts like, “Thank you for the text!!!" or "Is there anything I can do to help anyone? Other than no power, my family is safe."

Learn How You Can Bolster Your People Operations for 2024

If you want to take control of absenteeism in 2024 and create attendance stats that will make your competitors jealous, TeamSense would like to help you. We don’t negotiate trade policies. We don’t predict hurricanes or earthquakes. What we can do is help you build stronger digital connections with your deskless workforce and then show them that you care when the unexpected happens.

About the Author